2 months ago

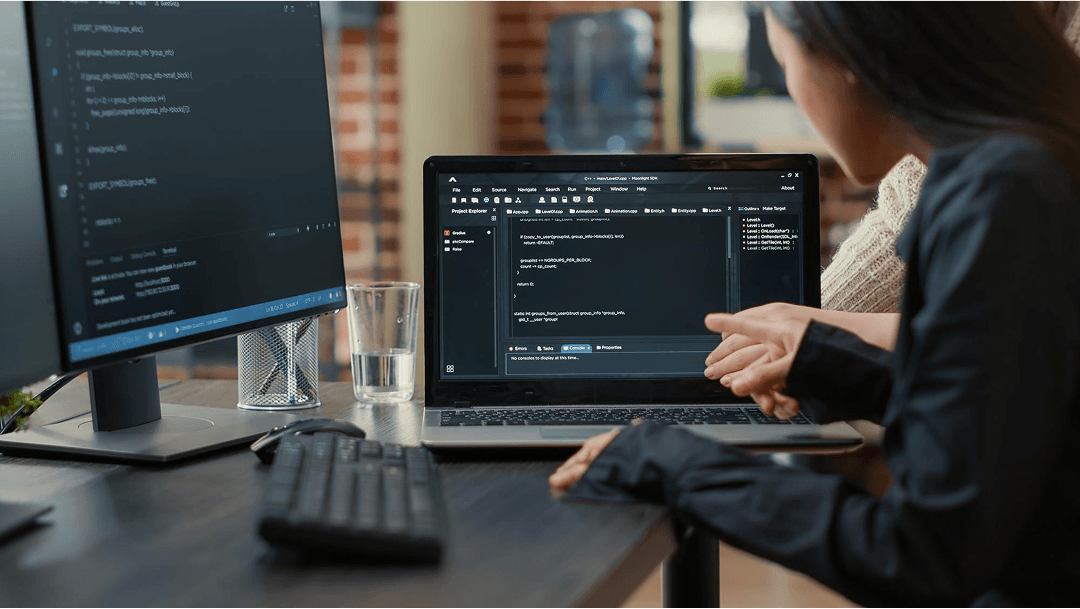

Software Development

Software Development Company Insights: Why AI Is Essential for Modern Manufacturing

Software Development Company

AI Development

Insight

In today’s modern manufacturing landscape, software is a core driver of efficiency, integration, and innovation.

As a trusted software development company, we go beyond building technology, we act as strategic digital transformation partners for manufacturing businesses.

We design and develop custom software solutions tailored to manufacturing operations, including production systems, inventory management, machine integration, and real time data platforms. Our solutions are built to support industry 4.0 initiatives, AI-driven automation, and smart factory environments.

Unlike off-the-shelf software, our custom manufacturing solutions are flexible, scalable, and secure designed to adapt to evolving market demands and operational complexity. Software serves as the critical link between business processes, industrial machines, and data intelligence.

We help manufacturers transform complex operational challenges into reliable, measurable, and future-ready software systems that improve productivity, visibility, and long term competitiveness.

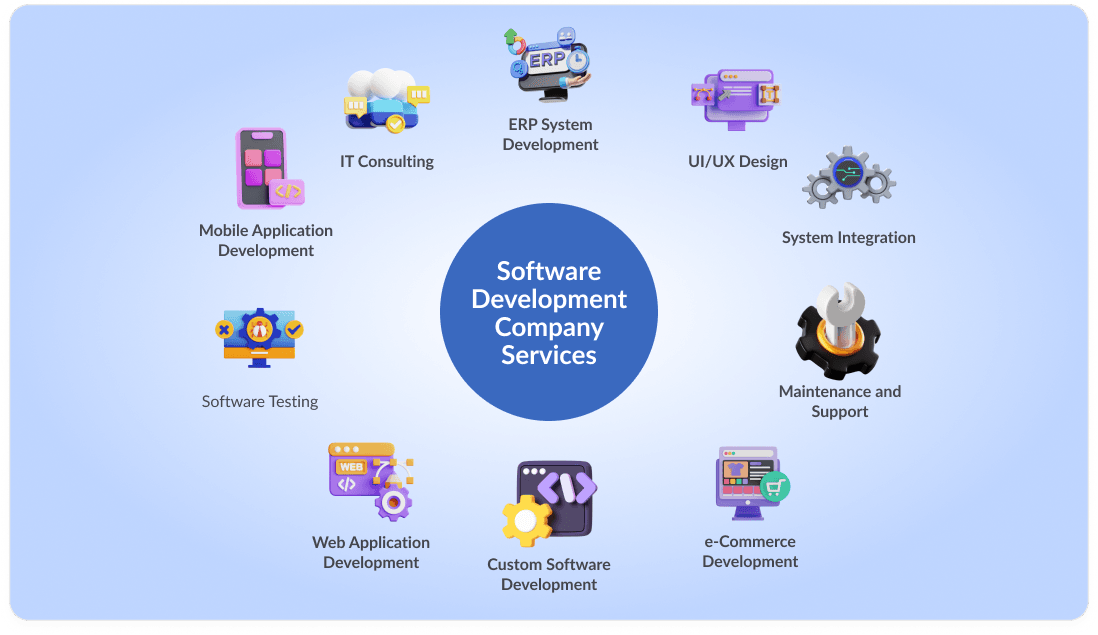

Key contributions of a software development company in modern manufacturing.

- Development of integrated systems such as ERP, MES, and supply chain management tailored to factory workflows.

- Implementation of IoT and AI for real time production monitoring, predictive maintenance, and machine performance optimization.

- Automation and data analytics that enable data-driven decision-making, reduce downtime, and improve product quality.

- System security and scalability to ensure manufacturing operations remain reliable as the business grows.

In modern manufacturing, software development is the core of digital transformation. Without software, digital transformation cannot succeed, as every process from production planning to decision making relies on integrated digital systems.

- Software Development as the Foundation of Digital Transformation

Digital transformation in manufacturing begins with system modernization through software, software enables the digitization of manual processes, cross department data integration, and real time operation visibility. Systems such as ERP, MES, and industrial data platforms form the core foundation of this transformation.

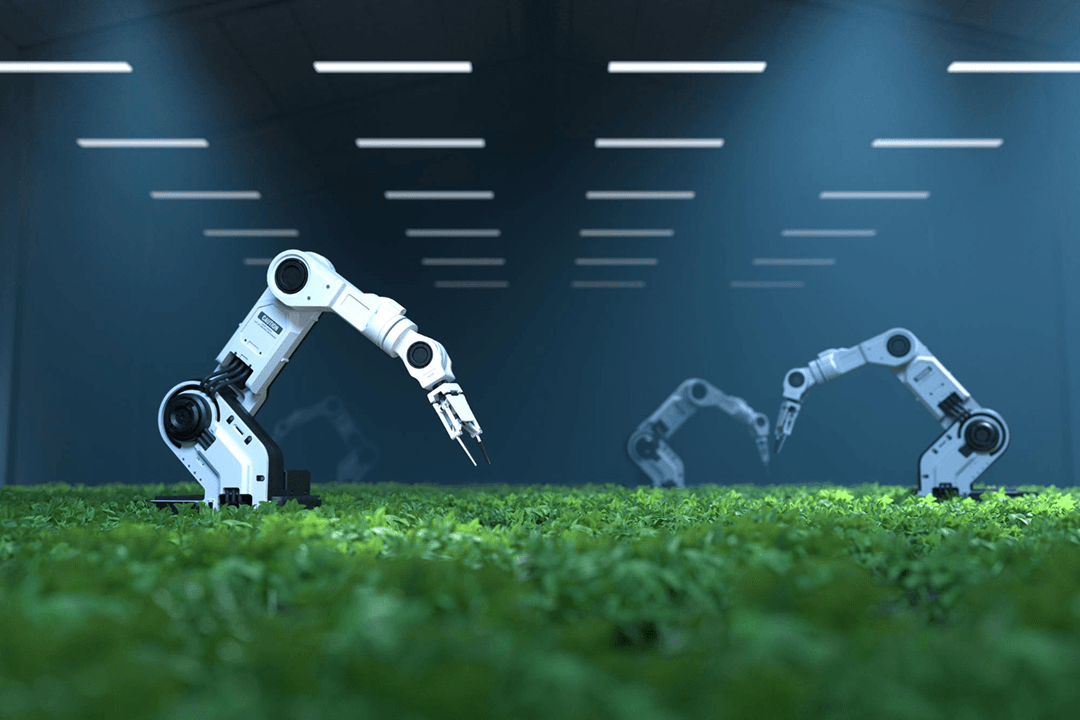

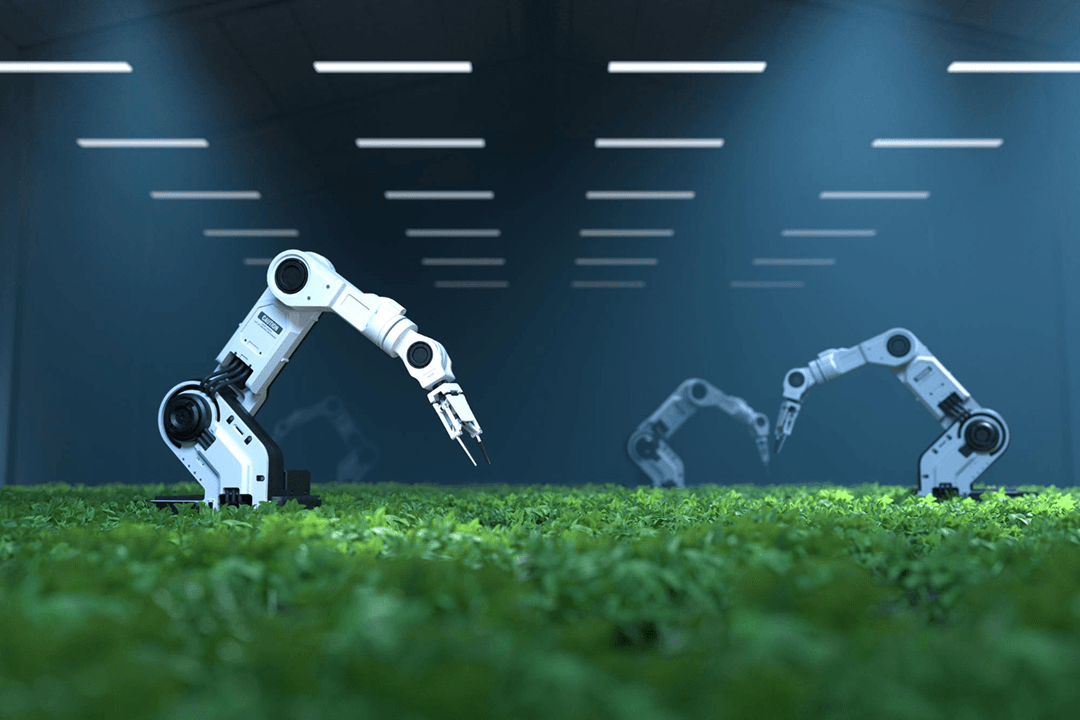

- Software as the Driver of Manufacturing Automation

Manufacturing automation does not rely solely on machines, but on software that controls, orchestrates, and optimizes automated processes. Software plays a key role in:

• Automatically controlling production workflows.

• Integrating machines, robots, and IoT sensors

• Enabling data driven quality control and maintenance.

Without the right software, automation cannot be efficient or scalable.

- Software as the Brain of Smart Factories

Smart factories represent the highest evolution of modern manufacturing, with software acting as the central brain. Through AI development, analytics, and real time monitoring systems, software enables factories to:- Predict machine failures through predictive maintenance.

- Adaptively optimize production processes

- Respond quickly to changing market demands.

- End to End Integration for Future Ready Operations

Custom software development connects the entire manufacturing ecosystem from supply chain and production to distribution into a single integrated system. This creates operations that are more agile, efficient, and prepared to meet future industrial challenges.

Digital transformation provides strategic direction, manufacturing automation delivers efficiency, and smart factories enable operational intelligence. Software development serves as the connecting element between all three, making it a key factor in the success of competitive and sustainable modern manufacturing.

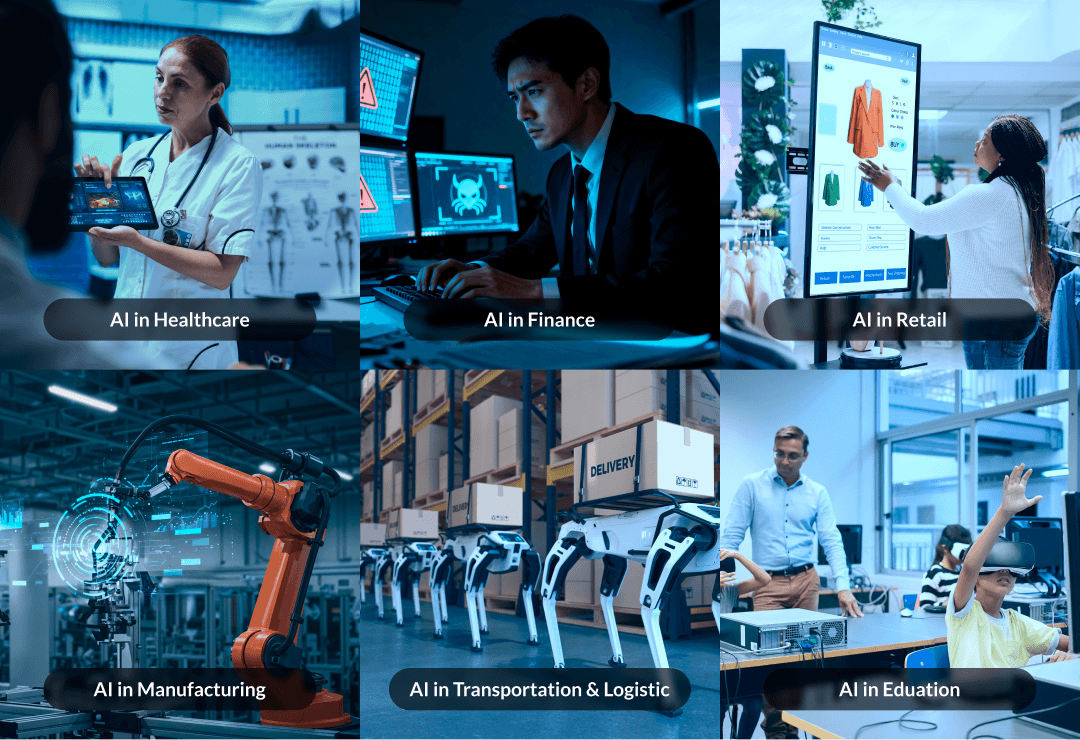

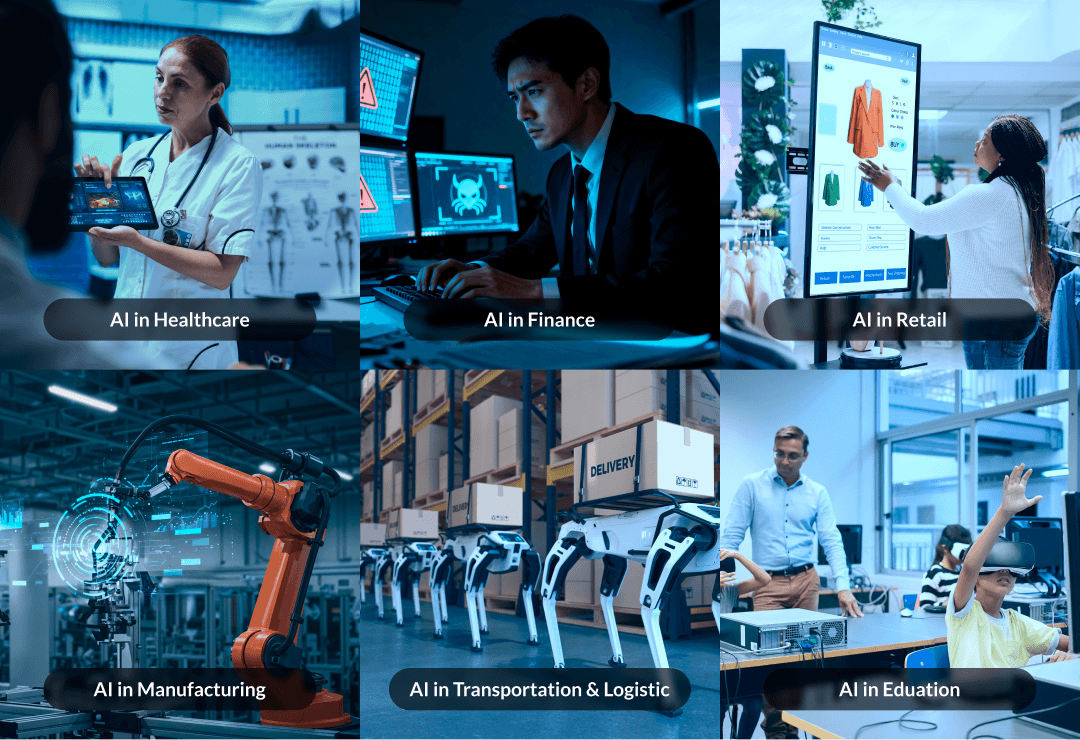

The Rise of Artificial Intelligence in Manufacturing Processes

The manufacturing industry is undergoing a major transformation driven by the increasing adoption of artificial intelligence in manufacturing.

Artificial Intelligence (AI) is no longer merely supporting technology, it has become a core component in creating production processes that are more efficient, intelligent, and competitive.

From automation to data driven decision making, Artificial Intelligence (AI) is reshaping how factories operate in the modern industrial era. Artificial intelligence (AI) plays an increasingly critical role in manufacturing due to its ability to process large volumes of data, identify patterns, and make fast, accurate decisions.

Artificial Intelligence in Manufacturing: The Foundation of Smart Manufacturing

AI development in manufacturing is used to improve production efficiency, product quality, and operational reliability. By leveraging data from machines, sensors, and production systems, artificial intelligence enables manufacturers to analyze production data in real time, identify operational patterns, and continuously optimize processes.

With the right software support, AI development helps increase productivity, reduce human error, and maintain consistent product quality forming the foundation of smart, data-driven manufacturing operations.

Industrial AI Applications for Operational Efficiency

The application of AI in industry spans multiple areas, including:

- Production data analysis to increase output and reduce waste

- Computer vision for automated quality inspection

- Supply chain optimization and production planning

Today, a wide range of industrial artificial intelligence (AI) applications are being implemented across manufacturing environments, from production analytics and computer vision based quality inspection to supply chain optimization.

These applications enable manufactures to make faster, more accurate while simultaneously reducing operational costs. Compared to manual approaches, AI driven solutions deliver greater speed, precision, and consistency in operational decision making.

AI-Powered Production Lines: Adaptive and Flexible Manufacturing

AI-powered production lines can automatically adjust production speed, workflows, and operating parameters based on real time data. The result is a production process that is more flexible, consistent, and capable of responding to changing market demand without compromising product quality.

By adapting dynamically to machine conditions, market demand, and material availability, AI-powered production lines, supported by intelligent software, become more scalable, resilient, and ready to handle the rapid pace of modern industrial change.

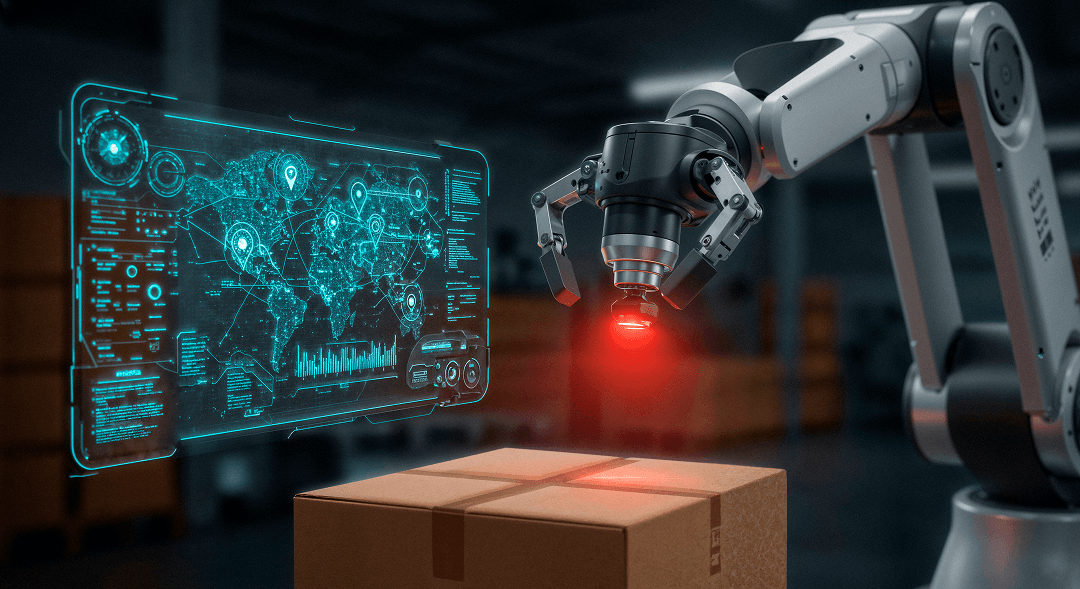

Predictive Maintenance: Reducing Downtime with AI

One of the most significant benefits of AI development in manufacturing is predictive maintenance. By analyzing historical data and current machine conditions, AI can predict potential failures before they occur.

This approach helps manufacturers reduce unexpected downtime, lower maintenance costs, extend asset lifespan, and improve overall operational reliability.

The Role of a Software Development Company in AI Manufacturing

As a software development company, we design, develop, and integrate AI solutions tailored to manufacturing needs. From industrial data processing and custom AI system development to seamless integration with ERP and MES platforms, software plays a critical role in ensuring successful AI adoption in modern factories. The rise of artificial intelligence (AI) in manufacturing processes marks a major shift towards smarter, more efficient, and data driven factories.

Key benefits of Integrating AI with Manufacturing Systems

Integrating Artificial Intelligence (AI) with manufacturing systems has become a strategic move for companies aiming to improve operational efficiency and competitiveness. By leveraging AI-driven efficiency, automation and real time data analytics, modern manufacturing operations can become smarter, faster, and more accurate.

Some of the key benefits include:

- AI-Driven Efficiency in Manufacturing Process

The first key benefit is AI-driven efficiency, which enables manufacturing systems to automatically optimize production processes based on real time data. AI helps streamline workflows, reduce bottlenecks, and improve machine utilization. The result is higher productivity without the need for significant additional resources. - Cost Reduction Through Automation

One of the primary benefits of AI integration is cost reduction through automation. AI reduces reliance on manual processes, minimizes human error, and lowers operational costs. In addition, AI-powered automation helps manufacturers reduce downtime, material waste, and unplanned maintenance expenses - Improve Product Quality with AI

Another important benefit is improved product quality with AI development, achieved through consistent quality monitoring and analysis. Using technologies such as computer vision and machine learning, AI can detect product defects in real time and ensure quality standards are consistently met.

This leads to higher customer satisfaction while reducing defects and rework. - Real-Time Data Analytics for Faster Decision-Making

AI integration enables real-time data analytics that provide full visibility into production conditions.

Data from machines, sensors, and production systems are analyzed instantly to support faster and more accurate decision-making. With data-driven insights, manufacturers can proactively respond to issues and opportunities. - The Role of Software Development Companies in AI Integration

Software development companies play a critical role in integrating AI into existing manufacturing systems. Through custom solution development, ERP and MES integration, and the deployment of secure and scalable AI technologies, software developers ensure that AI delivers measurable and sustainable business impact.

Challenges and Considerations When Implementing AI Solutions

Although Artificial Intelligence (AI) offers significant benefits to the manufacturing industry, its implementation comes with various challenges. Understanding AI integration challenges, data security in manufacturing, effective change management, and workforce upskilling is essential to ensure that Ai adoption is successful and sustainable.

Here is a detailed explanations:

- AI Integration Challenges in Manufacturing Systems

One of the main challenges is integrating AI with existing manufacturing systems. Many companies still rely on legacy systems that were not designed to support modern AI technologies. Without proper software architecture planning, this integration can lead to technical complexity, operational disruption, and limited scalability. - Data Security in Manufacturing

AI implementation requires large volumes of data, including sensitive production and operational information. Data security in manufacturing environments is a critical concern due to the increasing risk of data breaches and cyberattacks. AI systems must be built with high security standards to protect data and ensure uninterrupted factory operations. - Change Management for Manufacturers

AI-driven transformation is not only a technological shift but also a cultural one. Change management becomes a major challenge for manufacturers accustomed to conventional processes. Without clear communication and a structured adoption strategy, internal resistance can hinder the successful implementation of AI. - Workforce Upskilling with AI

AI adoption demands new skills from the workforce. Workforce upskilling with AI is essential to ensure employees can work effectively alongside intelligent technologies. Training and skills development are required to help teams leverage AI optimally, rather than feeling threatened by automation.

Software development companies play a critical role in helping manufacturers overcome these challenges through artificial intelligence strategy planning, custom software development, secure system integration, and support for change management and technical training. This approach ensures that artificial intelligence (AI) is not only implemented, but also delivers real and measurable business value.

Implementing AI solutions in manufacturing requires technological readiness, strong data security, effective change management, and workforce development. With the right strategy and the support of an experienced software development company, these challenges can be transformed into opportunities to build smarter, more efficient, and future-ready manufacturing operations.

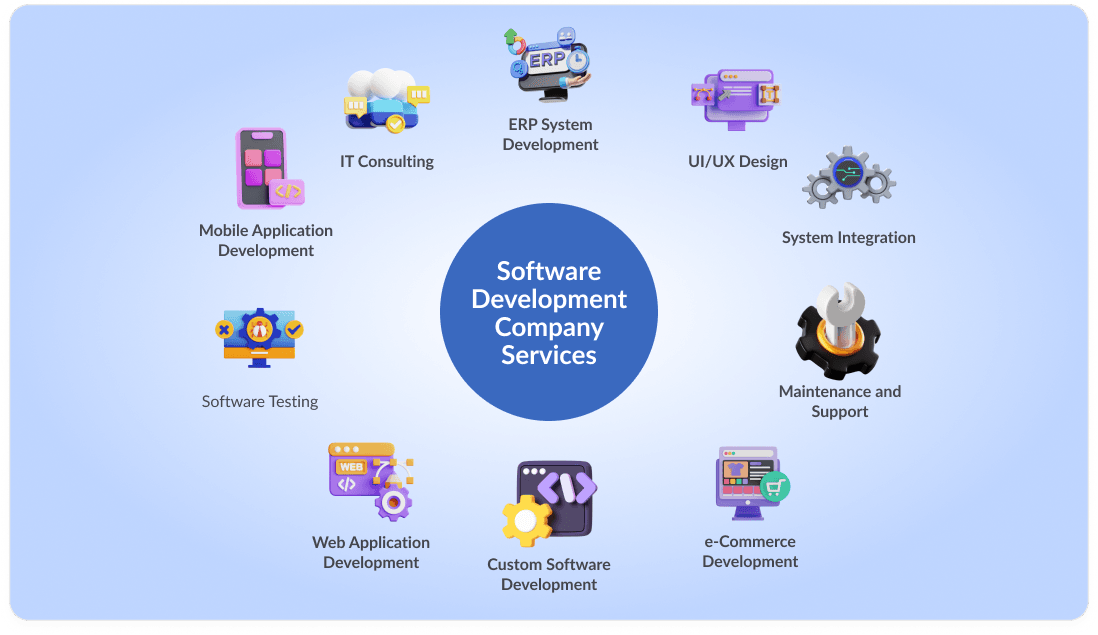

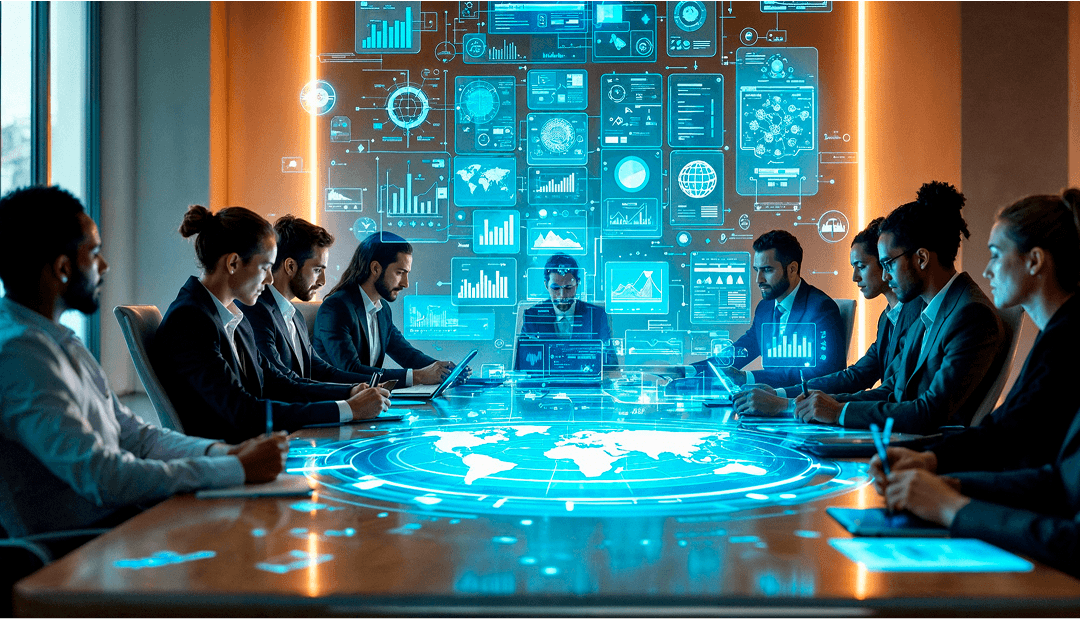

The Role of Software Development Companies in Enabling Smart Manufacturing

Smart manufacturing lies at the core of industry 4.0, where digital technologies, automation, and artificial intelligence (AI) are integrated to create intelligent and adaptive manufacturing processes. In this transformation, software development companies play a strategic role as key enablers, bridging business needs, technology, and factory operations.

As technology partners, software development companies do more than build applications. They help establish sustainable digital foundations. With expertise in software engineering, AI, and industrial system integration, software development companies ensure that smart manufacturing delivers tangible business value.

- Custom Software Solutions for Industry 4.0

Every enterprise manufacturing company has unique processes, challenges, and business objectives. Therefore, custom software solutions for Industry 4.0 are essential to the success of smart manufacturing. Software development companies design tailored solutions such as ERP, MES, and IoT platforms that align with factory workflows, ensuring systems are flexible, scalable, and future-ready. - Collaboration with Software Developers as a Key to Transformation

Smart manufacturing cannot be achieved through technology alone, it requires close collaboration with software developers. Through a collaborative approach, software development companies help manufacturers translate operational needs into integrated digital solutions that are easy for internal teams to adopt and scale. - End to End Automation Services for Integrated Operation

Software development companies provide end to end automation services, covering requirements analysis, system architecture design, software development, and machine and data integration. This end-to-end approach ensures manufacturing processes run automatically, efficiently, and seamlessly within a unified digital ecosystem. - Tailored AI Implementation Strategies for Manufacturing

Implementing Ai in smart manufacturing requires a precise and measurable strategy. Tailored AI implementation strategies enable manufacturers to adopt AI gradually, based on their technological and business readiness. Software development companies play a key role in identifying high-impact AI use cases such as predictive maintenance, quality inspection, and production optimization

The role of software development companies is crucial in enabling smart manufacturing. Through custom software solutions, strategic collaboration, end to end automation services, and tailored AI implementation, manufacturers can accelerate digital transformation and remain competitive in the industry 4.0 era.

Future Trends: How AI Will Continue to Shape the Manufacturing Sector

Artificial Intelligence (AI) will continue to be a key driver in the evolution of the manufacturing industry. As technology advances and efficiency demands increase, the future of smart manufacturing will rely even more

on the integration of AI, data, and intelligent digital systems.

Software development companies play a vital role in adopting and integrating future AI technologies into manufacturing systems. Through custom software development, AI and IoT integration, and future-ready system architectures, software development companies help manufacturers remain relevant, agile, and competitive in a rapidly evolving industrial landscape.

Below are key trends shaping the future of AI-driven manufacturing:

- Future of Smart Manufacturing

The future of smart manufacturing is defined by factories that are increasingly autonomous, connected, and adaptive. AI enables manufacturing systems to monitor, analyze, and optimize production processes in real time. With scalable software support, factories can respond to changes in market demand with greater speed and precision. - Emerging Technologies in Factories

A range of emerging technologies in factories will accelerate manufacturing transformation, including generative AI, digital twins, intelligent robotics, and edge computing. These technologies enable production process simulations, improved machine efficiency, and more accurate data-driven decision-making. - Industrial IoT and Machine Learning Trends

Trends in Industrial IoT (IIoT) and machine learning will further strengthen connectivity and intelligence within manufacturing systems. IoT sensors collect data from machines and production environments, while machine learning analyzes this data to identify patterns, predict failures, and optimize operational performance. - Adaptive Supply Chains Powered by AI

Ai will also shape adaptive supply chains that are more flexible and responsive. Through predictive analytics and AI-driven forecasting, manufacturers can manage inventory more effectively, anticipate supply chain disruptions, and rapidly adjust distribution strategies based on real-time market conditions.

Artificial intelligence (AI) will continue to shape the future of the manufacturing sector through smart factories, emerging factory technologies, the integration of IIoT and machine learning, and adaptive supply chains. With the right digital strategy and the support of a software development company, manufacturers can leverage these trends to create sustainable long term competitive advantage.

Conclusion: Leveraging Expert Software Development and Advanced AI for Competitive Advantage in Manufacturing

In the face of increasingly intense industry competition, enterprise manufacturing companies must position an

AI-driven innovation strategy at the core of their business transformation. The effective use of AI and software

development not only improves operational efficiency but also unlocks opportunities for continuous

innovation.

- AI-Driven Innovation Strategy as the Foundation of Competitiveness

An AI based innovation strategy enables manufacturers to optimize production processes, improve product quality, and accelerate decision making. With a well planned approach, AI becomes a key enabler for creating long term business value and market differentiation. - Choosing the Right Digital Transformation Partners

The success of digital transformation heavily depends on selecting experienced digital transformation partners. A software development company acts as a strategic partner, designing digital architectures, integrating AI into manufacturing systems, and ensuring solutions are scalable, secure, and future ready. - Staying Competitive Through Technology Adoption

In the Industry 4.0 era, staying competitive through technology adoption is no longer optional, it is essential. Manufacturers that proactively adopt AI, IoT, and automation technologies are better prepared to respond to market changes, supply chain disruptions, and evolving customer demands. - Next Steps Toward Smart Manufacturing Solutions

The next steps toward smart manufacturing solutions begin with assessing digital readiness, identifying high impact AI use cases, and collaborating with software development companies that understand industrial requirements. This phased approach ensures transformation efforts are effective and deliver measurable result

By combining expert software development capabilities with advanced AI technologies, enterprise manufacturing companies can build a strong and sustainable digital foundation. This is the key to achieving competitive advantage, driving innovation, and ensuring long-term relevance in the future of the manufacturing industry.

Ready to Accelerate Your Smart Manufacturing Journey?

Partner with us BTS.id an expert software development company to unlock the full potential of AI-driven manufacturing.

From custom software solutions to advanced AI implementation, we help you build scalable, secure, and futureready manufacturing systems.

Talk to our experts today, and take the next step toward smarter, more competitive manufacturing.

HIT US UP

BRIDGE TECHNOLOGY SERVICES

HIT US UP

BRIDGE TECHNOLOGY SERVICES

Your request has been sent, please wait for our reply

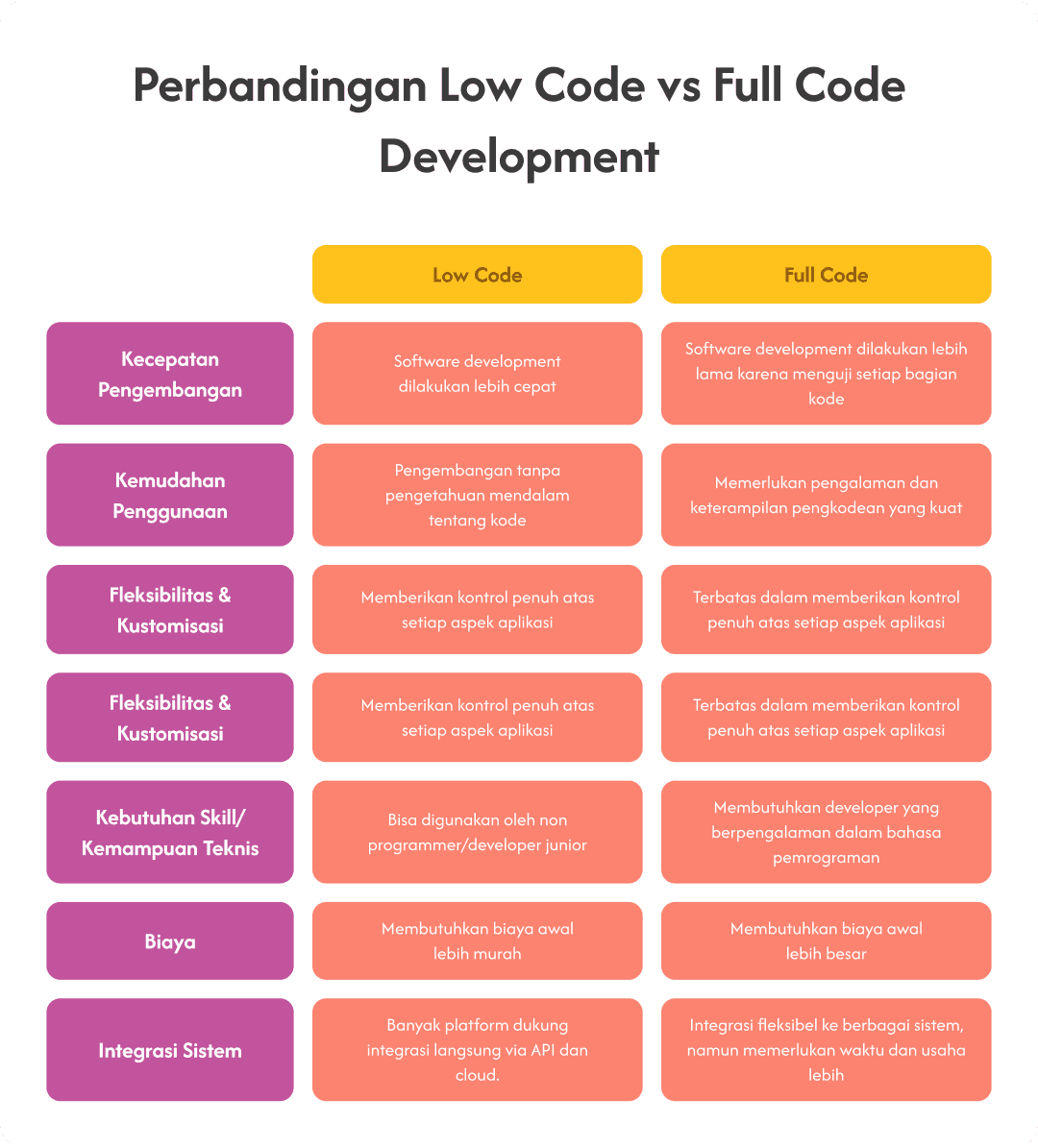

Dunia pengembangan aplikasi terus berkembang seiring kemajuan teknologi. Kini, berbagai pendekatan telah muncul, dari pengembangan Low-Code, yang memungkinkan pengembangan aplikasi tanpa memerlukan keterampilan coding mendalam, hingga pengembangan Full-Code yang memberikan fleksibilitas tertinggi bagi developer berpengalaman.

Bagi startup dan perusahaan besar, memilih pendekatan yang tepat untuk pengembangan aplikasi sangat penting. Dua pilihan yang sering dihadapi adalah low code dan full code.

Aplikasi semakin populer karena kegunaan dan aksesibilitasnya. Namun dengan begitu banyak software development di luar sana, mungkin akan sulit untuk menentukan jenis pengembangan mana yang terbaik untuk perusahaan bisnis Anda. Ketika membangun platform Internet of Things (IoT), banyak yang merasa bingung memilih antara menggunakan low code platform atau full code development. Kedua pendekatan ini memiliki kelebihan dan kekurangannya masing-masing.

Dalam dunia pengembangan, pemilihan antara low code dan full code dapat menentukan seberapa efisien dan cepat aplikasi yang Anda buat.

Low code platform menawarkan kemudahan dalam pengembangan dengan lebih sedikit menulis kode.

Sementara full code development memberikan kebebasan dan kontrol penuh atas setiap aspek pengembangan aplikasi. Kedua pendekatan ini dapat digunakan untuk membangun platform, tetapi pilihan terbaik sangat bergantung pada kebutuhan proyek yang sedang dijalankan.

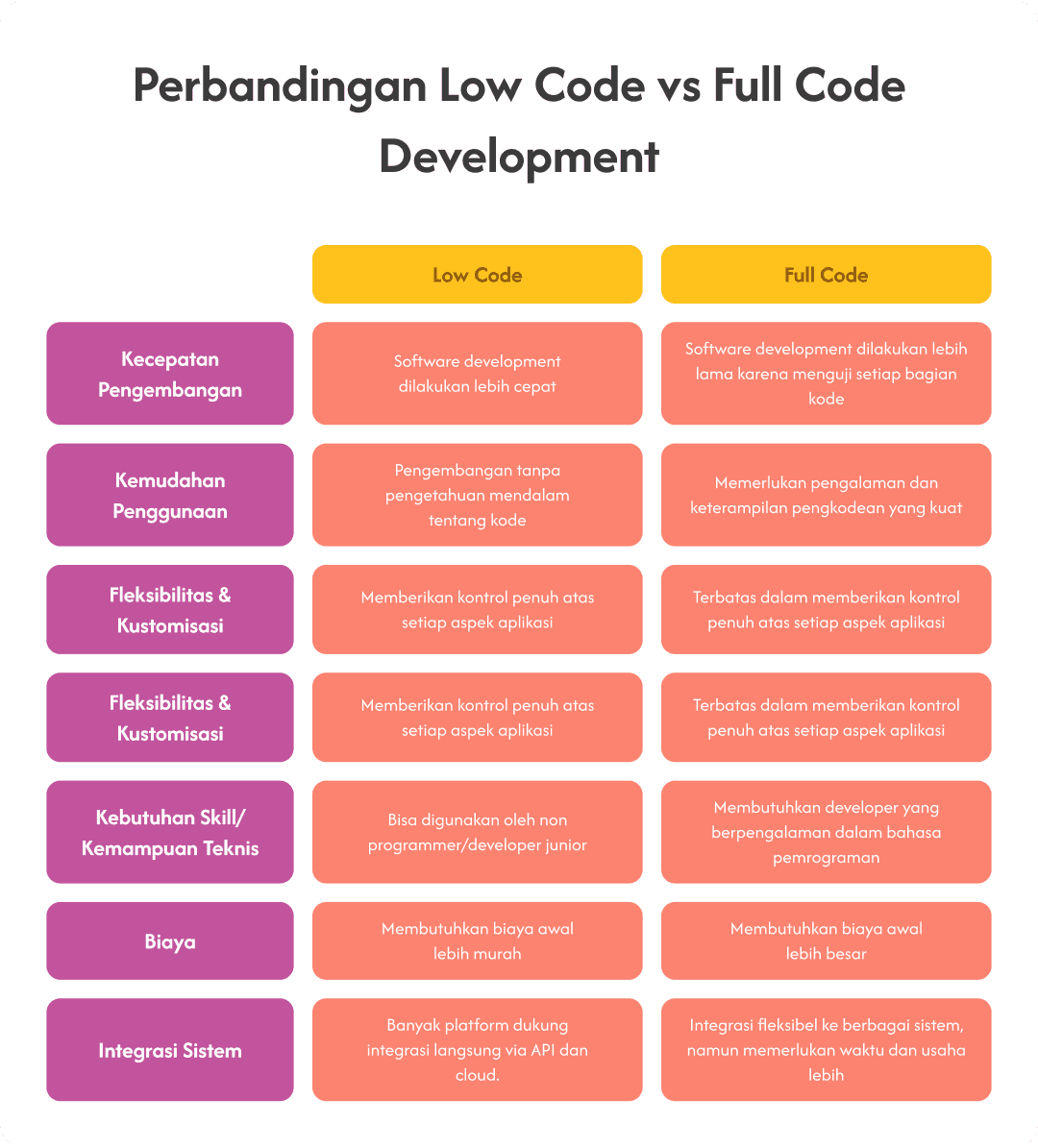

Low code vs full code adalah perbandingan antara dua pendekatan dalam software development, yang berbeda dari segi tingkat penulisan kode dan fleksibilitasnya.

Apa itu Low Code dan Apa itu Full Code?

Low code platform adalah pendekatan software yang memungkinkan pengguna untuk membangun aplikasi dengan sedikit menulis kode atau bahkan tanpa menulis kode sama sekali.

Dengan menggunakan low code platform, Anda bisa mempercepat pembuatan aplikasi tanpa harus menguasai keterampilan pemrograman mendalam.

Platform ini menawarkan antarmuka grafis yang memungkinkan anda drag-and-drop komponen aplikasi seperti database dan API, sehingga sangat cocok untuk prototyping cepat.

Sebaliknya, full code development adalah metode software development yang melibatkan penulisan seluruh kode aplikasi dari awal hingga selesai. Pendekatan ini memberikan fleksibilitas dan kontrol penuh kepada developer, memungkinkan mereka untuk menyesuaikan setiap detail dari aplikasi yang mereka buat, termasuk dalam membangun platform yang sangat kompleks dan spesifik. Jika Anda membutuhkan fungsionalitas yang sangat terperinci, full code adalah pilihan yang tepat.

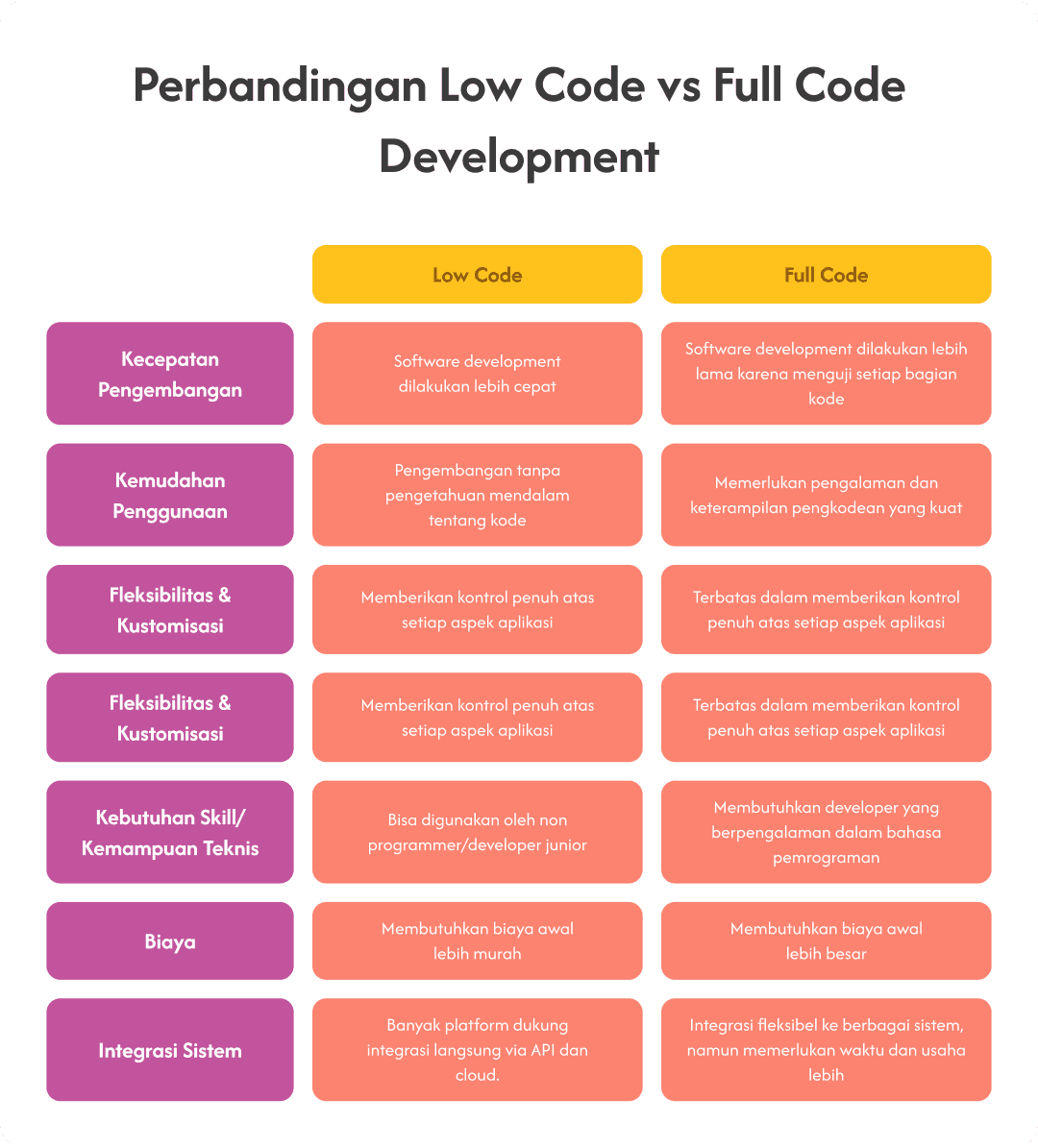

Berikut ini adalah perbandingan kelebihan low code platform dan full code development:

- Kecepatan Pengembangan

Banyak orang memilih low code platform, karena proses software development bisa dilakukan lebih cepat dengan menggunakan antarmuka visual, Anda bisa menghindari banyak tahapan pemrograman manual yang memakan banyak waktu. Di sisi lain, full code development memerlukan waktu lebih lama karena menulis dan menguji setiap bagian kode.

- Kemudahan Penggunaan

Low code platform memungkinkan pengembangan tanpa memerlukan pengetahuan mendalam tentang kode. Hal ini sangat cocok untuk tim yang ingin fokus pada ide kreatif tanpa harus berurusan dengan kompleksitas teknis.

Sebaliknya full code development memerlukan pengalaman dan keterampilan pengkodean yang kuat untuk bisa mengelola dan mengembangkan secara efektif.

- Fleksibilitas dan Kustomisasi

Full code development memberikan kontrol penuh atas setiap aspek aplikasi, sehingga Anda bisa mengubah dan menyesuaikan platform sesuai dengan kebutuhan spesifik proyek Anda.

Low code platform lebih terbatas dalam hal ini karena fitur yang tersedia sering kali sudah ditentukan oleh platform yang digunakan.

- Kebutuhan Skill atau Kemampuan Teknis

Low code platform bisa digunakan oleh non programmer atau developer junior, serta banyak dokumentasi dan template yang dapat mempermudah adopsi,

Full code development membutuhkan developer yang berpengalaman dalam bahasa pemrograman dan cocok untuk tim teknis profesional.

- Biaya

Low code platform membutuhkan biaya awal lebih murah, karena proses pengembangan lebih cepat dan bisa dilakukan oleh tim kecil, dan cocok untuk perusahaan kecil hingga menengah atau tim dengan anggaran terbatas.

Full code development perlu biaya awal lebih besar, karena membutuhkan tim developer, infrastruktur, dan waktu pengembangan lebih lama namun hemat dalam jangka panjang jika sistem terus dikembangkan dan dimiliki sendiri (tanpa biaya lisensi)

- Integrasi Sistem

Dalam low code platform banyak platform yang mendukung integrasi out of the box (API, database populer, service cloud), namun bisa terbatas jika butuh integrasi dengan sistem legacy atau protokol khusus.

Untuk full code development integrasi tak terbatas, bisa dihubungkan ke sistem internal, database custom, atau protokol unik, namun membutuhkan waktu dan effort lebih tapi fleksibel.

Keunggulan dan kekurangan Low code dan Full code dalam software development:

- Low Code

- Keunggulan:

- Salah satu keunggulan utama low code platform adalah efisiensi dalam proses pengembangan karena memungkinkan developer membangun aplikasi dengan cepat tanpa harus menulis kode dari awal.

Platform ini juga menawarkan titik tinggi, sehingga dapat dikustomisasi sesuai dengan kebutuhan bisnis yang kompleks. - Low Code mendukung integrasi dengan sistem yang lebih besar, memungkinkan perusahaan untuk menghubungkan aplikasi mereka dengan berbagai layanan pihak ketiga.

- Kemampuan dalam mengakomodasi baik pengembang profesional maupun tim bisnis yang ingin terlibat dalam proses pengembangan.

- Biaya awal lebih rendah, tidak membutuhkan banyak developer berpengalaman. Platform biasanya sudah menyediakan hosting, database, autentifikasi, dan lain-lain sehingga efisien untuk bisnis kecil menengah atau perusahaan dengan sumber daya terbatas.

- Salah satu keunggulan utama low code platform adalah efisiensi dalam proses pengembangan karena memungkinkan developer membangun aplikasi dengan cepat tanpa harus menulis kode dari awal.

- Kekurangan:

- Meskipun menawarkan permulaan yang tinggi, low code tetap memerlukan keterampilan teknis dalam implementasinya sehingga tidak sepenuhnya dapat digunakan oleh non-developer.

- Ketergantungan pada platform low code juga bisa menjadi kendala karena perusahaan harus menyesuaikan diri dengan batasan yang diberikan oleh penyedia layanan.

- Dalam proyek yang sangat kompleks, penggunaan low code platform masih memerlukan intervensi developer untuk memastikan aplikasi berjalan sesuai dengan kebutuhan bisnis.

- Faktor lainnya adalah potensi masalah keamanan dan skalabilitas jika tidak dirancang dengan benar sejak awal.

- Kustomisasi terbatas, tampilan UI, flow data atau struktur database hanya bisa diubah dalam batas tertentu. Jika butuh integrasi spesifik atau algoritma unik, bisa sangat sulit (bahkan tidak bisa dilakukan sama sekali).

- Keunggulan:

- Full Code

- Keunggulan

- Full code development memiliki keunggulan fleksibilitas tanpa batas, bisa membangun fitur unik dan logika bisnis kompleks sesuai kebutuhan spesifik.

- Full code tidak terbatas pada kemampuan atau batasan platform pihak ketiga, dan sangat cocok untuk proyek yang memerlukan algoritma khusus, sistem real-time, AI, atau skala besar,

- Full code memiliki kontrol menyeluruh atas semua aspek aplikasi: arsitektur, performa, UI/UX, keamanan, dan deployment, serta dapat menyesuaikan struktur data, routing, autentikasi, enkripsi dan lainnya sesuai standar perusahaan.

- Developer bisa memilih sendiri stack teknologi, framework, dan layanan yang digunakan.

- Kekurangan

- Full code development memerlukan waktu pengembangan lebih lama. Semua komponen dibangun dari nol atau library open-source, mulai dari setup awal, database, logika bisnis, hingga tampilan semuanya perlu dikerjakan manual, sehingga tidak cocok untuk yang butuh hasil cepat atau prototipe instan.

- Full code membutuhkan tim dengan skill yang tinggi. Full code harus memiliki developer berpengalaman dalam berbagai bidang seperti backend, frontend, database, keamanan, deployment dan lainnya.

Kesalahan kecil dalam penulisan kode bisa menyebabkan bug atau celah keamanan. - Full code perlu biaya lebih untuk merekrut developer, arsitek sistem, UI/UX designer, dan tim DevOps, juga perlu investasi untuk infrastruktur seperti server, CI/CD tools, dan lainnya.

- Full code cocok untuk investasi jangka panjang, tapi kurang efisien jika hanya untuk solusi cepat atau satu kali pakai.

- Keunggulan

Software house Indonesia berperan penting dalam membantu bisnis memilih pendekatan software development yang tepat, baik full code development maupun low code platform. Software house Indonesia dapat memberikan saran, konsultasi dan pengalaman yang dibutuhkan untuk menentukan solusi yang paling sesuai dengan kebutuhan bisnis dan tujuan yang ingin dicapai. Software house Indonesia memiliki posisi strategis dalam membantu perusahaan untuk memilih metode pengembangan aplikasi yang efisien, sesuai anggaran, dan selaras dengan tujuan bisnis.

Berikut beberapa peranan software house Indonesia dalam memilih pendekatan yang tepat untuk bisnis Anda:

- Analisa Kebutuhan Bisnis Secara Mendalam

Sebelum menentukan pendekatan pengembangan, software house akan menggali tujuan bisnis dan masalah utama yang ingin diselesaikan dengan teknologi. Menilai kompleksitas fitur, target pengguna, dan kebutuhan jangka panjang. Menganalisa anggaran, waktu yang tersedia, dan tingkat urgensi. Dengan ini software house bisa merekomendasikan apakah low code platform sudah cukup atau perlu full code development untuk memenuhi kebutuhan.

- Menyesuaikan Solusi dengan Sumber Daya Perusahaan

Software house Indonesia akan mempertimbangkan:- Apakah klien memiliki tim IT internal atau bergantung penuh pada pihak eksternal.

- Seberapa besar kemampuan dan pengembangan lanjutan dari klien.

- Apakah bisnis klien akan terus berkembang (butuh sistem yang bisa di-scale atau dimodifikasi bebas)

Dengan demikian, software house bisa menyarankan pendekatan: - Low Code: jika klien ingin solusi cepat, murah dan mudah dipelihara.

- Full Code: jika klien butuh fleksibilitas tinggi dan sistem kompleks.

- Menyediakan Tim Teknis yang Sesuai dengan Pendekatan Terpilih

Jika klien memilih low code, software house Indonesia akan menyiapkan tim yang menguasai platform low code tertentu (misal: OutSystem, Microsoft Power Platform).

Jika klien memilih full code, software house akan menyiapkan developer yang ahli dalam teknologi yang relevan (misal: React, Node js, Laravel, Java, Python, dsb).

Hal ini penting agar pengembangan berjalan efisien dan hasilnya optimal.

- Memberikan Layanan Scalable dan Jangka Panjang

Software house Indonesia bisa menyusun roadmap teknologi sebagai berikut:- Mulai dari prototipe sederhana (low code) kemudian migrasi ke sistem penuh (full code) jika sistem perlu dikembangkan lebih jauh.

- Langsung membangun sistem kustom dengan full code jika dari awal sudah disiapkan untuk pertumbuhan besar.

Pendekatan bertahap ini membantu bisnis menghemat biaya tanpa kehilangan arah pengembangan.

Kapan harus memilih Low code atau full code untuk proyek Anda?

Berdasarkan kondisi nyata, kebutuhan bisnis dan tujuan jangka panjang dapat dijelaskan sebagai berikut:

Pilih Low Code jika:

- Proyek butuh cepat jadi.

Cocok untuk prototipe, MVP atau validasi ide bisnis, dan bisa membangun aplikasi dalam hitungan hari atau minggu. - Anggaran terbatas, minim biaya pengembangan awal dan tidak perlu membentuk tim developer besar.

- Kebutuhan aplikasi sederhana, misal sistem approval internal, dashboard laporan, form digitalisasi dan lainnya, serta tidak membutuhkan logika bisnis yang rumit atau integral kompleks.

- Tidak ada tim developer internal, sehingga cocok untuk perusahaan yang tidak punya tim IT. Aplikasi tetap bisa dibangun dan dipelihara dengan bantuan vendor atau citizen developer.

- Skala penggunaan terbatas, aplikasi digunakan oleh tim kecil atau organisasi internal, sehingga tidak butuh skalabilitas tinggi atau performa maksimum.

- Butuh kolaborasi cepat antar tim IT dan non-IT, analisa bisnis, product owner atau manajer bisa ikutmerancang aplikasi langsung di platform visual.

Pilih Full Code jika:

- Aplikasi butuh kustomisasi tinggi dan fitur unik. Misal: e-commerce besar, sistem pembayaran, platform AI/ML, game atau aplikasi dengan aturan bisnis kompleks.

- Skalabilitas dan performa sangat penting, harus mampu melayani ribuan hingga jutaan pengguna dengan stabil.

- Standar keamanan tinggi, biasanya diperlukan untuk industri seperti fintech, healthtech, e-gov atau sistem data sensitif, memerlukan kontrol penuh atas enkripsi, autentikasi dan audit.

- Integrasi dengan sistem atau infrastruktur khusus, misal integrasi dengan ERP, SAP, IoT, mesin industri atau API kompleks, yang mana tidak bisa dilakukan secara fleksibel di low code platform.

- Perusahaan punya rencana teknologi jangka panjang, dimana sistem akan terus dikembangkan, diperluas an disesuaikan. Perlu kendali penuh atas arsitektur dan kode sumber (source code)

- Tim teknologi internal sudah siap, memiliki developer sendiri dan DevOps sendiri, sehingga mampu melakukan pengembangan, testing dan pemeliharaan berkelanjutan.

Dalam dunia bisnis yang semakin terdigitalisasi, keputusan dalam memilih pendekatan pengembangan aplikasi low code atau full code tidaklah bisa dilakukan sembarangan tanpa pertimbangan.

Setiap pilihan memiliki konsekuensi terhadap biaya, waktu, skalabilitas, keamanan dan masa depan sistem.

Disinilah peran software house Indonesia menjadi sangat penting. Software house Indonesia tidak hanya membangun aplikasi, tetapi juga bertindak sebagai konsultan teknologi strategis yang memahami kebutuhan spesifik industri lokal, keterbatasan sumber daya bisnis, dan arah pertumbuhan perusahaan.

Keputusan teknologi yang tepat akan menghemat waktu, biaya dan energi Anda. Keputusan tepat dimulai dari bekerja sama dengan partner teknologi yang tepat. Jika Anda masih ragu dalam memilih low code platform atau full code development, melibatkan software house Indonesia yang berpengalaman adalah langkah yang bijak dan cerdas untuk meminimalkan resiko dan memaksimalkan hasil.

BTS.id merupakan salah satu software house di bandung, dan terbaik di Indonesia yang telah banyak dipilih oleh perusahaan-perusahaan besar di Indonesia untuk membuat dan mengembangkan custom software sesuai dengan kebutuhan mereka. Hal ini menjadikan software developer BTS.id sebagai Technology Partner terbaik untuk membantu Anda menemukan solusi bisnis yang tepat untuk perusahaan Anda.

BTS.id menerapkan agile methodology dalam setiap layanan software development-nya untuk memastikan solusi yang adaptif, efisien, dan selaras dengan kebutuhan bisnis Anda. Pendekatan yang kolaboratif dan iteratif dari BTS.id dapat membantu perusahaan menghadirkan produk digital yang inovatif dan juga berkualitas tinggi.

Untuk mendapatkan solusi digital terbaik hanya BTS.id software company dan IT consultant terbaik untuk bisnis Anda.

No companies are prepared for COVID-19 outbreak.

When the earliest cases of the novel coronavirus were found December last year, no one could have predicted that the pandemic will lead us to the environment we are currently living and working in, and that the situation will escalate so quickly in just a few months.

The implementation of PSBB or Pembatasan Sosial Berskala Besar (Large-scale Social Restrictions) and strong encouragement of work from home policies has caused businesses from accross different sectors to falters, resulting in economic disruption that has caused more than 2 millions of Indonesian workers being laid off and placed on furlough.

With the vaccine has yet to be found, social distancing may remain in place for a longer time. Harvard Researchers even predicted that in US, intermittent distancing may be required into 2022 unless a treatment or vaccine becomes available. Given examples of South Korea and Singapore, effective distancing is essentials because it could reduce the strain on health care systems and enable contact tracing and quarantine to be feasible.

Wearing a facemask, social distancing and frequent hand-washing will become parts of the ‘new normal’ from now on, said the head of the National Disaster Mitigation Agency (BNPD) who is also the head of the National COVID-19 Task Force.

However, prolonged distancing may have negative economic consequences that will lead to a global recession, where 1.1 million to 3.78 million of Indonesian people could fall into poverty, and 2.9 million to 5.2 million workers could lose their jobs.

To keep your business afloat and recover from the impact caused by the corona virus pandemic, it is important to ensure that everyone is healthy and productive. In the past few months, many businesses has undergone digital transformation and incorporate new technologies and strategies as a way to remain productive and effective under highly challenging circumstances.

As one of the leading system integrator in Indonesia, BTS.id is ready to support your IT needs for digital transformation in two ways:

1. Project-Based

In a project-based model, a dedicated team is assigned to handle the whole process of a project, from the beginning to the end. The team may consist of people with all of the skills required to take care of the project, such as software developers, UI/UX designers, software testers, project managers, etc. Usually, one team will focus on managing no more than two projects at the same time, making it a suitable option for companies with no internal IT team.

By adopting this model, you will be able to bring together people with different skillsets at a more reasonable cost. Furthermore, with the team focus on less deliverable, they can also be more productive and less distracted, which is crucial for the success of the project.

2. Team-based Outsourcing

With a team-based outsourcing, you are the one who manage the project. A distributed team or personnel will contribute to your projects, which can be two or more at the same time. Unlike the project-based outsourcing, this outsourcing model allows you to hire both a specific team member and a full, complete team. Whether it is just a developer, UI/UX designer, or a software tester, you can hire only the people you need for your projects.

The team-based outsourcing model allows the team members to switch from one task to another across multiple projects, therefore more agile and flexible. As an additional support, this solution is recommended for companies that already have their own in-house IT team.

Why work with BTS.id?

1. Remote software development with strict procedural rules

We put our clients’ and employees’ health on top of our priority, hence the reason why during the pandemic, we encourage you to choose remote software development instead. To maintain physical distancing during the development process, in person or face-to-face meetings will be replaced with remote, online, or virtual one, supported by the latest technology such as video conferencing and collaborative tools that can bridge the distance gap between you and the development team.

Not only that, we also follow strict personal hygiene, cleaning, and sanitising procedure to ensure that the development team will stay healthy and fit throughout the development process.

We are communicative, responsive, and commited to deliver your projects with 100% success rate, even remotely.

2. Hands-on experience with enterprise, medium, and big companies

For years, even before the pandemic, we have been successfully managing remote development and providing outsourcing service for enterprises and medium to big companies across different sectors. Our clients including private bank, minimarket chain, and large mining companies in Indonesia.

Whether you are a company with small IT department or no IT team at all, BTS.id is ready to guide you with remote digital transformation and system integration. From project manager to developer and even a complete development team, we will always provide you with the best engineer we have.

3. Provide you with the right solution

We solve your problem by providing you with the right solution approach. With our services ranged from consultation through system implementation, as well as final system testing or verification, our priority is to make solutions that are tailored to meet your company’s specific needs and size.

Looking for the best System Integrator in Indonesia to help you with remote software development? Consult your needs and entrust the system integration to BTS.id (Bridge Technology Service). Contact us:

Phone : (+62 22) 6614726

Email : info@bts.id

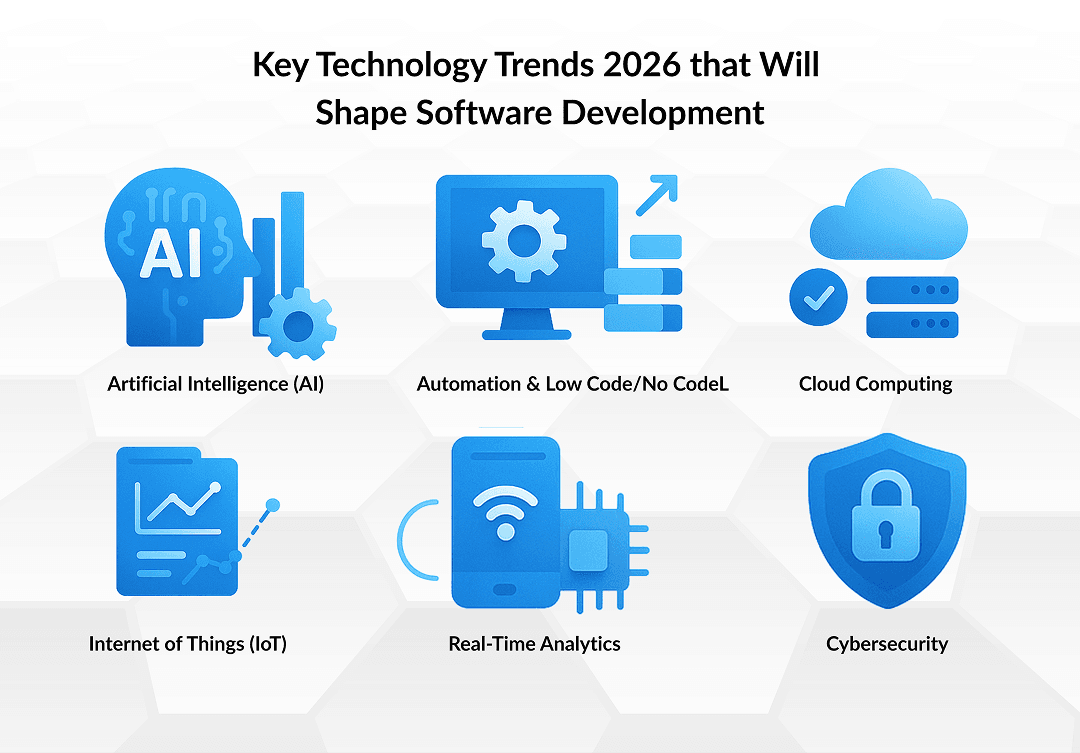

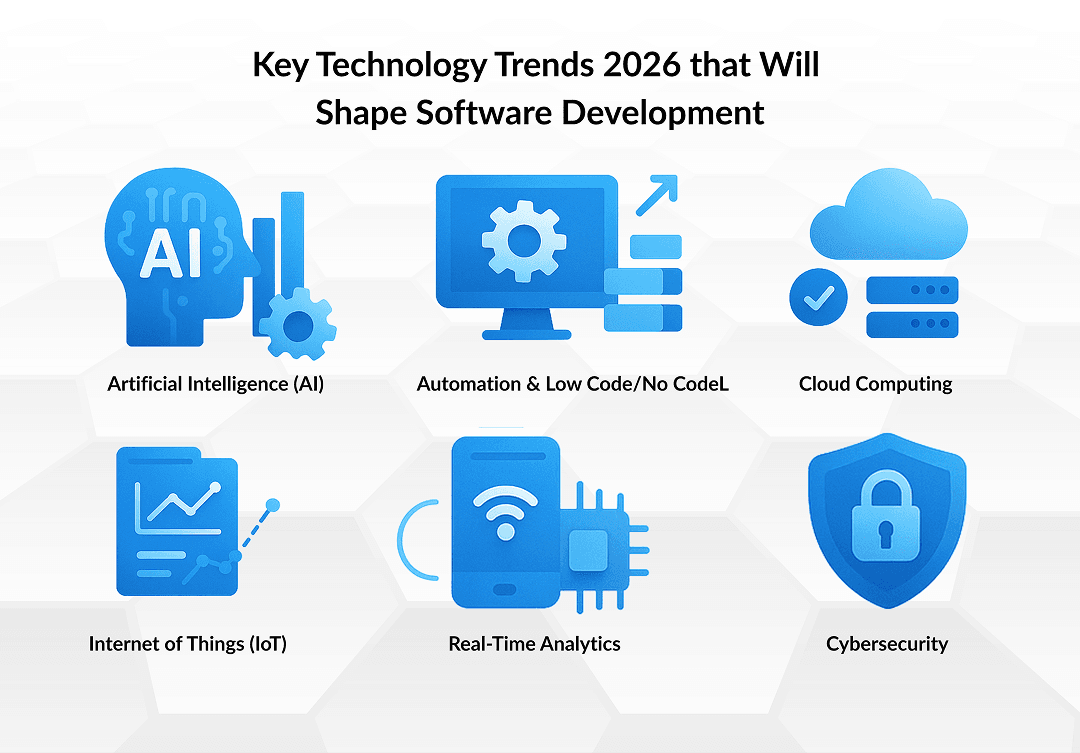

2026 marks a crucial year for software development companies, where Artificial Intelligence (AI) and the cloud are no longer just trends but the core foundations of business transformation.

In business technology trends 2026, business technology will increasingly focus on artificial intelligence, the cloud, and intelligent automation.

Companies are leveraging Artificial Intelligence for faster and more accurate decision making, while the cloud is the foundation for flexible, secure, and easily scalable systems. This technology integration helps businesses improve efficiency, accelerate innovation, and remain competitive amidst rapid market changes. The role of software development companies is not merely as technology vendors, but as strategic partners helping clients adapt and grow in the digital era.

Business technology trends for 2026 will be driven by the acceleration of digital transformation, where companies are transforming their work practices, business models, and services through technology. In this process, businesses must adapt to Artificial Intelligence (AI) to improve efficiency, automation, and decision making quality.

Meanwhile, adopting cloud solutions is a key foundation for more flexible, scalable, and AI-ready business systems.

- Business Technology Trends 2026

Business technology trends in 2026 demonstrate a shift from mere technology adoption to strategic technology utilization. Key focuses include:

• Artificial Intelligence (AI) and Generative AI for data analysis, automation, and service personalization.

• Cloud-native and Hybrid cloud as business infrastructure standards

• Hyper Automation to accelerate end-to-end operational processes.

• Zero trust based cybersecurity as digital risks increase.

These trends emerge as businesses are required to be more agile, efficient, and adaptive to market changes. - Adapting to AI

Adapting to Artificial Intelligence means integrating AI into core business processes, such as supply chain, customer service, marketing, and product development, using AI for data-driven decision making, and preparing human resources, processes, and governance for the ethical and effective use of Artificial Intelligence.

Without AI development, digital transformation in 2026 will be slow and suboptimal. - Embracing Cloud Solutions

The cloud is the technical foundation that enables AI and digital transformation to thrive. Its key benefits are:

• Scalability to adapt to business needs.

• Agility in application development and deployment.

• Cost efficiency through a pay-as-you-go model.

• Security and reliability continuously improved by cloud providers.

Without the cloud, AI implementation would be expensive, slow, and difficult to develop.

These four concepts form a mutually supportive ecosystem, where businesses that want to survive and thrive in 2026 must implement AI- and cloud-powered digital transformation, not as a mere technology project, but as a long-term strategy for competitive advantage.

In the ever-evolving digital era, digital transformation is key for businesses to remain relevant and competitive.

In this process, software development companies play a crucial role as strategic partners, helping companies adopt technology effectively and sustainably.

- Software Development Partners as Strategic Partners

As software development partners, software development companies not only build applications but also deeply understand business beads. They collaborate with clients to design technology solutions that align with business goals, improve operational efficiency, and support long-term growth. - Digital Transformation Services for Business Modernization

Through digital transformation services, software development companies help businesses modernize legacy systems, integrate technologies like AI and cloud, and automate work processes. These services enable companies to be more agile, responsive to market changes, and ready to face future digital challenges. - Tech Consulting Firms in Determining Technology Direction

As tech consulting firms, software development companies provide strategic guidance in selecting the right technology. From digital roadmap development and system architecture planning to technology risk management, this role ensures digital transformation is on track and delivers optimal ROI. - Custom Software Solutions for Specific Needs

Every business has unique processes and challenges. Therefore, custom software solutions are a crucial part of digital transformation. Software development companies design custom solutions tailored to their clients' industry and operational needs, ensuring technology truly impacts productivity and competitiveness.

Why Are Software Development Companies Important in Digital Transformation?

In digital transformation, the role of software development companies is crucial for:

- Helping businesses adapt to technological changes.

- Providing scalable and future-ready solutions.

- Strategically integrating AI development and the cloud.

- Increasing efficiency, security, and innovation.

The role of software development companies in digital transformation is crucial for modern businesses. As software development partners, digital transformation service providers, tech consulting firms, and custom software solution developers, they help companies transform holistically, not just following trends, but building a strong digital foundation for the future.

Navigating the Rapid Evolution of AI Technologies

The rapid development of Artificial Intelligence (AI) is transforming the way businesses operate across various industries. To remain competitive, companies need to understand how to leverage AI strategically, not just follow trends.

This is where Artificial Intelligence (AI) integration strategies, AI adoption, and machine learning consulting become crucial.

- AI integration Strategies for Effective Implementation

AI integration strategies help businesses integrate AI into existing systems and processes. This approach ensures AI technology runs in harmony with business infrastructure, from ERP and CRM to analytics systems, resulting in tangible business efficiencies and value. - Artificial Intelligence Adoption as Phased Process

Artificial intelligence adoption is not just about technology, but also organizational readiness. Businesses need to prepare data, human resources, and governance for sustainable AI adoption. A phased approach helps mitigate risks and ensures AI truly supports long-term business goals. - Machine Learning Consulting for Purpose-Built Solutions

Through machine learning consulting, businesses receive guidance in selecting the most relevant AI development models and use cases. Machine learning consultants help design solutions that are accurate, scalable, and aligned with industry needs, ensuring that AI investments deliver optimal ROI. - Automating Business Processes with AI

One of the greatest benefits of AI is automating business processes with AI. From chatbot-based customer service to predictive analytics and operational management, AI helps accelerate workflows, reduce costs, and improve productivity.

Navigating the evolution of AI requires a well thought out strategy and the right technology partners. By combining AI integration strategies, Artificial Intelligence adoption, machine learning consulting, and automating business processes with AI, businesses can maximize AI’s benefits and prepare for the digital future.

Leveraging Cloud Computing for Scalable Growth and Innovation

In an era of accelerating digital transformation, cloud computing has become a key foundation for businesses seeking to achieve scalable growth and drive continuous innovation. Beyond simply moving data to the cloud, the right cloud strategy enables companies to increase agility, cost efficiency, and long-term competitiveness.

Why Cloud Computing Is Key to Business Growth

Cloud computing enables businesses to:

- Adjust system capacity in real time.

- Accelerate product development and launch.

- Reduce reliance on physical infrastructure.

- Support the integration of AI, big data, and automation.

With a pay-as-you-go model, companies can optimize costs while maintaining operational flexibility.

Cloud Migration Services: The Foundation of Digital Transformation

Cloud migration services help companies move applications, data, and workloads from on-premises systems to the cloud in a secure and structured manner.

A well planned migration process includes:

- System and data readiness assessment.

- Determining the migration strategy (rehost, refactor, replatform)

- Post migration security and performance testing.

A successful cloud migration provides system stability while opening up opportunities for further innovation.

Cloud Native Applications: Driving Faster Innovation

Cloud native application development enables businesses to build applications specifically designed for cloud environments. With microservices architecture, containers, and an API-first approach, companies can deploy faster and more flexibly, increase scalability without downtime, and simplify integration with AI and analytics services.

Cloud-native applications are key to improving time-to-market and business responsiveness.

Multi Cloud Environments: Business Flexibility and Resilience

Adopting multi cloud environments allows businesses to use multiple cloud providers for different needs.

Key benefits include:

- Avoiding vendor lock-in.

- Improving systems resiliency and availability.

- Optimizing costs and performance.

A multi-cloud strategy also helps companies meet cross regional regulations and compliance requirements.

Cloud Infrastructure Management: Optimal Operations

Without proper management, cloud computing can become complex. Cloud infrastructure management plays a critical role in ensuring:

- Monitoring systems performance and security.

- Optimizing cloud resources usage and security.

- Enforcing security and backup policies.

Effective cloud management ensures systems remain stable, secure, and efficient as businesses grow.

Cloud Computing as an Innovative Enabler

Cloud computing not only supports growth but also enables innovation. With the cloud, businesses can develop new digital products faster, test ideas through prototyping and experimentation, and integrate AI, IoT, and data analytics in a scalable manner.

This allows companies to innovate without significant infrastructure risk.

Ensuring Security and Compliance Amid New Tech Trends

The rapid advancement of technologies such as artificial intelligence and cloud computing presents significant opportunities for businesses, while at the same time introducing serious challenges related to security and regulatory compliance. In 2026, ensuring digital system security and data protection is no longer merely a technical requirement, but a critical component of long term business strategy.

Within the context of cybersecurity for businesses 2026, cyber threats are becoming increasingly sophisticated, as many attacks now leverage automation and AI-based technologies.

Business systems connected to the cloud and processing large volumes of data require a more proactive security approach.

Zero-trust architecture, real-time threat monitoring, and robust protection of cloud infrastructure have become the new standards for safeguarding business continuity and maintaining customer trust.

As Artificial Intelligence (AI) and cloud adoption increases, regulatory compliance in AI and cloud computing has also become a major focus. Governments and regulators in various countries are tightening regulations regarding data protection, ethical use of AI, and transparency of digital systems.

Businesses are required to ensure that the technology they use complies with regulations from the planning and development stages. A compliance-by-design approach helps companies avoid legal risks while safely accelerating the adoption of new technologies.

Furthermore, implementing data protection strategies is a key foundation for maintaining security and compliance. Effective data protection includes strict access management, data encryption, and reliable backup and recovery mechanisms.

With a well-developed data protection strategy, businesses can minimize the risk of information breaches and ensure data remains secure throughout its lifecycle.

Security and compliance in the new technology era are no longer standalone entities; they are integrated into the overall digital transformation. By leveraging modern security technologies and a structured approach, businesses can innovate with AI and the cloud without compromising security or regulatory compliance.

Ultimately, ensuring security and compliance amidst emerging technology trends is crucial for maintaining a business's reputation, sustainability, and competitiveness. Companies that effectively manage security and regulatory risks will be better prepared to face digital challenges and capitalize on technological opportunities in 2026 and beyond.

The Importance of Custom Solutions Versus Off-the Shelf Tools in 2026’s Market Landscape

As we enter 2026, the business landscape is increasingly competitive, driven by the acceleration of digital transformation. Companies no longer compete solely on price or product, but also on technological capabilities that support speed, efficiency, and innovation. In this context, the choice between custom software development and off-the-shelf software becomes a strategic decision that directly impacts long-term business growth.

- Custom Software vs. Off-the-Shelf Software

Off-the-shelf software is suitable for general needs and rapid implementation, especially for businesses that require instant solutions without custom development. However, this type of software usually has standard features that are not always relevant to unique business processes.

Custom software development is designed around specific business processes and objectives, so the technology fully supports the company's way of working, rather than forcing the business to adapt to the system.

Generic software often limits flexibility as a business grows, due to limitations in customization, integration, and scalability as data volume and complexity increase. Custom solutions are more adaptable to changing business strategies, allowing for the addition of features, the integration of new technologies, and rapid market adaptation. - Tailored Business Solutions

- Adapting technology to a company’s internal workflow helps eliminate unnecessary manual processes and increase team productivity.

- Optimal integration with existing systems, AI, and the cloud allows data to flow seamlessly, supporting advanced analytics and intelligent automation.

- Supports long term scalability and growth because the system is designed to scale as the business grows.

- Improve operational efficiency and data visibility so management can make faster and more accurate decisions.

- Competitive Advantage Through Customization

- Delivers unique features that are difficult for competitors to imitate because solutions are developed based on the company’s internal needs and strategies.

- Increase innovation speed and time to market, enabling businesses to respond to market changes faster than competitors.

- Provides a more relevant and personalized customer experience, which directly impacts customer loyalty and satisfaction.

- Strengthens business positioning in competitive markets, especially in industries with high-tech competition.

- Strategic Value in the 2026 Market Landscape

- High flexibility in the face of technological and regulatory changes, including AI, cloud, and new data policies

- Greater control over data, security, and system roadmaps, reducing reliance on third party vendors.

- More sustainable long term investment, as systems can be continuously developed without requiring a complete platform replacement.

- Technology serves as an enabler of business strategy, not just an operational tool, thus supporting long term growth and innovation.

Choosing the right software development company is a strategic step for businesses in 2026, as technologies like AI, cloud computing and automation become increasingly complex. When choosing a tech partner, companies need to evaluate more than just price and portfolio. Understanding business needs, industry experience, and technological capabilities are key factors in assessing the right candidate.

When evaluating custom software development firms in 2026, it's important to look at their project track record, development approach, readiness for the latest technology trends, and commitment to security and scalability. Furthermore, asking potential vendors questions, such as their work methods, collaboration models, post-launch support, and adaptability, helps businesses select a technology partner capable of not only building solutions but also supporting long-term growth.

In short, choosing the right tech partner means choosing a strategic partner who understands the business vision and is able to deliver relevant, scalable, and future ready technology solutions.

As we enter 2026, business success is crucially determined by a company's ability to future-proof its business technology strategy. Adopting AI and the cloud is no longer just a technology project, but a core strategy for increasing efficiency, scalability, and sustainable innovation.

By partnering with experts for innovation success, businesses can adopt AI and the cloud in a more targeted, secure, and tailored manner. Support from experienced technology partners helps companies mitigate risk, maximize investment value, and build a digital foundation ready to face future technological changes.

Prepare your business for 2026 with the right AI and cloud strategy.

Partner with an experienced custom software development company to build solutions that are scalable, secure, and ready to support long-term growth.

Contact us at BTS.id now, and begin your digital transformation with expert guidance focused on tangible results.

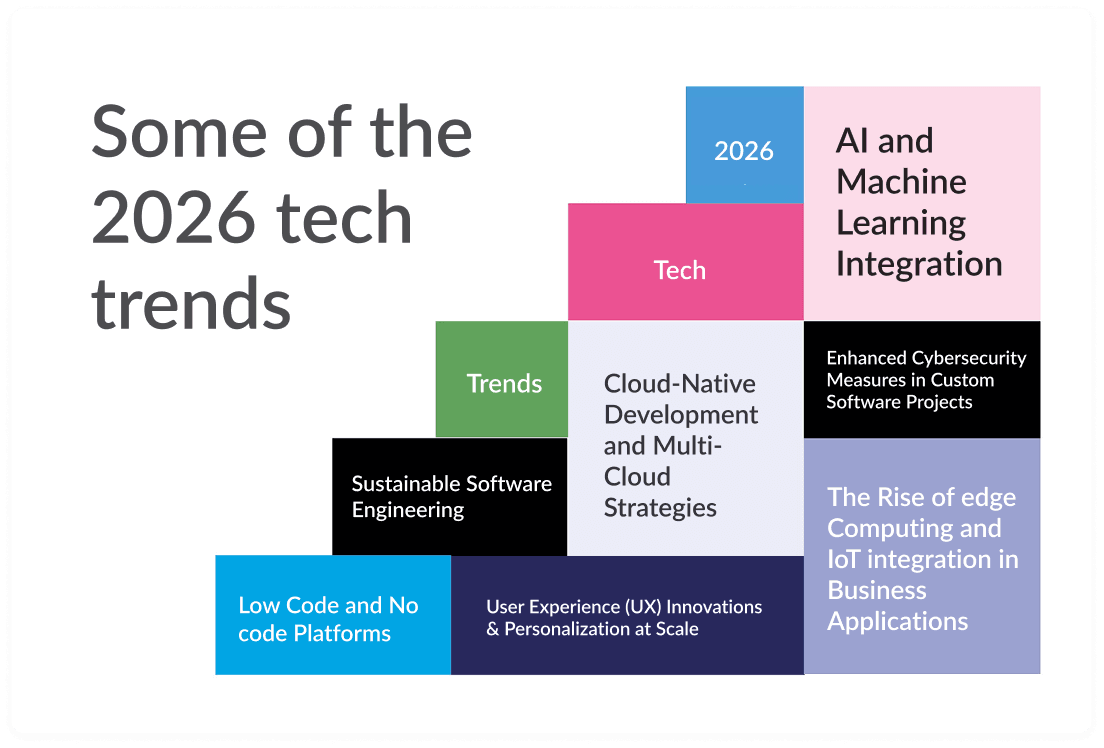

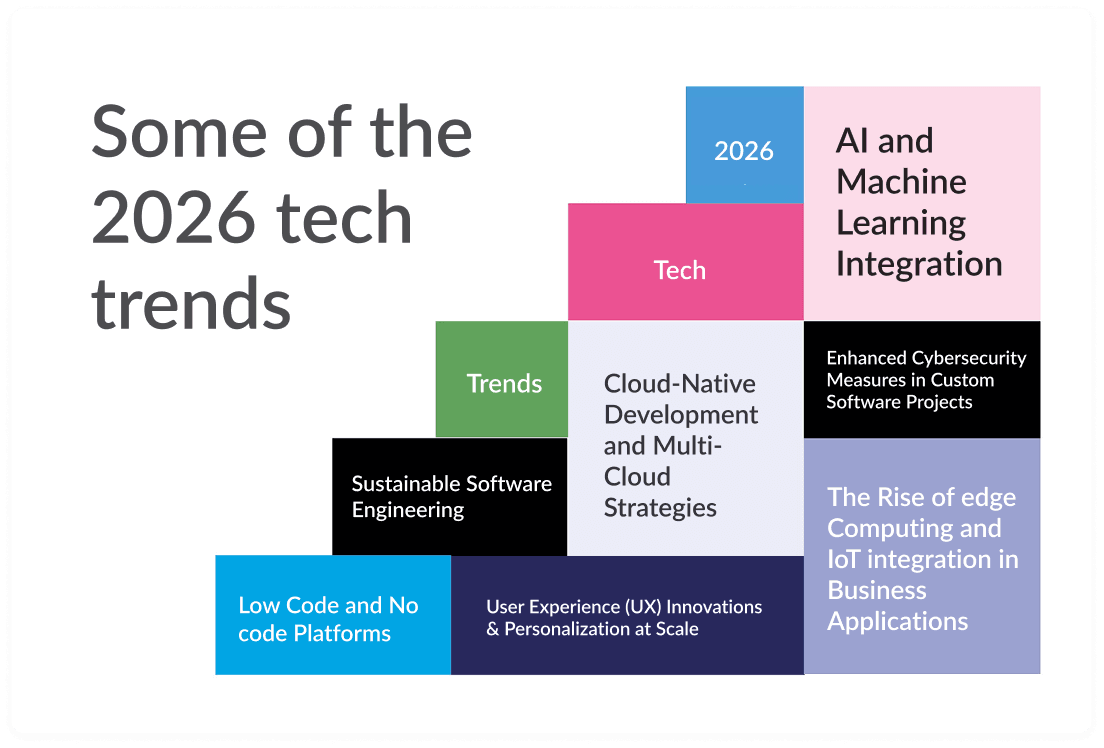

In 2026, software development companies are positioned at the forefront of rapid digital innovation, playing a critical role in shaping how modern businesses operate and compete. As organizations encounter increasingly complex operational challenges and significantly higher user expectations, we are witnessing a major shift toward solutions that are not only smarter and faster, but also deeply integrated across ecosystems.

Generative AI is redefining how applications are built and optimized, cloud-native architecture ensures unmatched flexibility and scalability, hyperautomation streamlines processes end-to-end with unprecedented efficiency, and zero-trust security has become a non-negotiable requirement in protecting digital assets.

For software development companies, 2026 tech trends are more than just technological advancements, they represent a new standard in delivering value.

Clients now expect digital products that can evolve quickly, integrate seamlessly, and withstand constant security threats. This places development teams in a strategic position, not only to adopt new technologies, but to proactively guide businesses through digital transformation, helping them build future-ready systems that accelerate growth, improve resilience, and maintain a competitive edge in an ever-changing landscape.

The 2026 tech trends will have a significant impact on the evolution of software development.

The evolution of software development is a journey from the early days of computers to the modern era, marked by technological advancements and paradigm shifts. It refers to how the processes, technologies, and methods of software creation have continuously changed over time.

From writing machine code directly, it progressed to high-level programming languages, and now it is moving toward faster methodologies like Agile and DevOps, while integrating advanced technologies such as AI/ML, microservices, and low-code/no-code platforms.

The evolution of software development is closely linked to digital transformation, with both driving each other. Digital transformation requires companies to accelerate innovation, automate processes, and provide better digital experiences. To meet these demands, software development must evolve to become faster, more flexible, and smarter.

The digital transformation that necessitates software evolution will impact technological advancements such as AI, machine learning, cloud computing, IoT, robotics, and automation. These advancements make business processes faster, more efficient, smarter, and more connected. Companies can create new products, enhance services, and respond to market changes more effectively. Technological progress is a key driver of both digital transformation and the evolution of software development.

Some of the 2026 tech trends, which represent the latest custom software developments that every company should know in 2026, are:

- AI and Machine Learning Integration: Shaping the Future of Custom Solutions

The integration of AI and machine learning into custom software solutions enables systems to become smarter, more automated, and capable of learning from data. This represents a transformative trend in the technology industry, where Artificial Intelligence (AI) and Machine Learning (ML) are no longer just additional features but core components of custom-designed software solutions tailored to meet specific business needs.

With these technologies, applications can:

• Predict user needs,

• Automate complex processes,

• Provide real-time recommendations,

• Improve the accuracy of business decisions.

Overall, AI and ML are shaping the future of custom solutions by delivering software that is more personalized, efficient, adaptive, and data-driven, making businesses more competitive in the digital era.

The four elements that from the core, mutually supportive components in AI and machine learning integration are as follows:- AI in Custom Software

Provides intelligence to applications, enabling software to understand context, analyse data, and respond intelligently. - Machine Learning Applications

Allows software to learn from data continuously improve accuracy and performance over time. - Intelligent Automation

Automate processes with AI/ML-based decision-making capabilities, rather than merely following static rules. - Predictive Analytics

Use ML algorithms to predict trends, risks, and future needs, making software more proactive.

- AI in Custom Software

- Low Code and No code Platforms: Accelerating Application Delivery

Low code and no code platforms are technologies that enable application development with minimal coding (low code) or even no coding at all (no code). These technologies will become highly important in 2026 as businesses increasingly demand applications that are fast, flexible, and easily customizable.

These platforms help businesses accelerate innovations, improve internal processes, and respond to market needs without waiting for lengthy development projects. In short, low code/no code offers an effective way to speed up application delivery in the 2026 era.

In shaping the modern application development ecosystem in 2026, there are four related elements:- Low Code Platforms 2026: Low code platforms provide visual tools and ready-to-use components, allowing developers to write minimal code. By 2026, these platforms will become the standard for accelerating enterprise software projects.

- No Code App Builders: Used by non-technical users to create applications without coding. They are an essential part of the low code/no code trend, expanding internal innovations capabilities within companies.

- Rapid Application Development (RAD): Low code and no code directly support RAD, a methodology focused on building applications very quickly, with instant prototyping and rapid iteration.

- Citizen Developers: These are users who leverage no code or low code to build applications, including:

• Operational staff,

• Marketing,

• Finance,

• HR.

• Product managers.

They can create their own solutions without waiting for the IT team.

These four elements accelerate innovation together, reduce the developer’s workload, and enable companies to release applications faster in 2026.

- Cloud-Native Development and Multi-Cloud Strategies

Cloud native development is an approach to building applications directly in the cloud environment using technologies such as microservices, containers, and serverless computing. This approach makes applications more scalable, faster, and easier to update.

Meanwhile, multi cloud on a single vendor, increase flexibility, and ensure systems remain operational even if one service experiences downtime.

Both trends are important in 2026 because they help companies build applications that are more resilient, efficient, and ready to grow in line with modern business needs.

The four interconnected components that form a modern cloud modernization ecosystem in 2026 are:

• Cloud Native Apps: A new way to build modern applications.

• Serverless Architecture: A part of cloud native that makes development more efficient.

• Multi Cloud Solutions: A deployment strategy that maximizes flexibility and resilience.

• Cloud Migration Trends 2026: The main driver prompting companies to adopt cloud native and multi cloud models.

These are key pillars that help businesses build applications that are more scalable, flexible, and future-ready in the 2026 era.

- Enhanced Cybersecurity Measures in Custom Software Projects

In 2026, security will be a top priority in custom software development. Companies are increasingly implementing advanced protections such as end-to-end encryption, multi layer authentication,

AI-based threat detection, and compliance with global standards. The goal is to protect sensitive data, prevent cyberattacks, and ensure applications are secure from design through deployment.

The following four key components are the main focus for modern companies:- Cybersecurity Best Practices 2026

The latest standards, such as zero trust, AI-based threat detection, end to end encryption, and continuous monitoring, ensure applications remain secure against evolving to achieve. - Secure Software Development Lifecycle (SSDLC)

Security is integrated into every stage of development. With SSDLC, vulnerabilities can be identified faster, mitigation costs are lower, and compliance is easier to achieve. - Data Privacy Regulations

Global and regional regulations require companies to handle data securely and transparently.

This drives the implementations of privacy by design, strict access controls, and regular audits in custom software. - Threat Detection Tools for Custom Solutions

AI/ML based tools help detect anomalies, block threats in real time, and provide proactive protection against modern attacks.

In 2026, security must be a foundational element of custom software development. By combining best practices, SSDLC, privacy compliance, and threat detection technologies, companies can build secure, modern solutions ready to face the risks of the digital world.

- Cybersecurity Best Practices 2026

- The Rise of Edge Computing and IoT integration in Business Applications

Edge computing processes data directly on devices or near the source, rather than in the cloud, making applications faster, more responsive, and efficient. When combined with IoT (Internet of Things), businesses can manage smart devices, sensors, and machines in real time.

This trend is important in 2026 because it helps companies enhance automation, accelerate decision making, and create smarter, more connected business applications.

• Edge computing trends 2026: Data processing closer to devices for high speed and efficiency.

• IoT-enabled solutions: Interconnected smart devices and sensors supporting business automation.

• Real-time data processing: Businesses can make instant decisions through rapid analytics at the edge.

• Connected devices integration: Integrating various devices for smarter, more responsive operations.

Edge computing accelerates data processing, IoT provides a network of data generating devices, and their integration allows companies to create smarter, more responsive, and scalable applications. The year 2026 will be an era where businesses rely on these technologies to improve efficiency, automation, and real time decision making capabilities.

- User Experience (UX) Innovations and Personalization at Scale

In 2026, UX innovation is no longer just about attractive design, but about how applications deliver truly relevant experiences for each user. Technologies such as AI, machine learning, and data analytics enable companies to create personalization at scale without compromising performance.

UX innovations provide more intuitive interfaces, adaptive navigation, and more human-like interactions.

Meanwhile, personalization at scale uses real time data to automatically tailor content, recommendations, and features to the needs of each user.

• UX design trends 2026 drive applications to be more intuitive, minimalist, and responsive, focusing on user comfort.

• Personalized user interfaces for custom apps leverage AI and real-time data to display content, recommendations, and layouts tailored to each user’s needs.

• Customer-centric development strategies ensure the entire development process focuses on the user experience, aligning personalization with UX innovation.

These elements create custom applications that are more personal, relevant, and satisfying, serving as a key business differentiation in 2026.

- Sustainable Software Engineering: Green IT Initiatives Gaining Momentum

Sustainable software engineering is an approach to custom software development that focuses on energy efficiency, reducing carbon, footprints, and using more environmentally friendly resources. By 2026, more companies are adopting Green IT initiatives such as optimizing cloud infrastructure, writing energy efficient code, and designing efficient architecture to reduce power consumption.

The goal is to create software that is lighter, more efficient, and sustainable, while supporting corporate environmental targets.

• Sustainable software practices 2026: Focus on reducing carbon footprints and improving energy efficiency in application development.

• Green coding techniques: Writing lightly, resource efficient code that minimizes computational waste.

• Energy efficiency application design: Application architectures that optimize the use of servers, cloud resources, and devices.

The practices create software that is more efficient, environmentally friendly, and sustainable.

- Navigating Regulatory Compliance in a Changing Digital Network

In the 2026 tech trends, companies must adapt to new regulations related to data, security, and privacy. Software development now needs to consider standards such as GDPR, PDPA, HIPAA, or other local regulations.

The goal is to ensure applications are secure, legally compliant, and able to adapt to continuously evolving regulations, helping businesses avoid legal risks and data breaches.

• Software compliance requirements 2026: The latest software compliance requirements in 2026 demanding stricter security, privacy, and data management.

• GDPR updates for developers: GDPR updates that developers must understand to ensure applications comply with privacy standards and user data protection.

• Industry specific regulations for bespoke software: Industry specific rules (healthcare, finance, government, etc) that must be applied in custom software.

Together, these form a modern compliance framework that companies must follow to keep custom software secure, legal, and regulation-ready in constantly changing digital work.

To face 2026, companies need to embrace innovation to stay relevant and competitive. Future-proofing your business with 2026 tech trends means preparing your business by following trends such as AI, cloud native, IoT, and modern cybersecurity, making systems more adaptive and ready for rapid changes.

Meanwhile, staying competitive through innovation adoption emphasizes the importance of strategically adopting new technologies not just following trends, but truly integrating them into business processes and software development.

The outcome is that organizations can build smarter, more efficient, and sustainable custom solutions while maintaining a competitive position in an increasingly dynamic digital era.

Digital transformation is no longer optional. It is a necessity.

With the latest trends such as AI/ML, cloud-native, low-code/no-code, and modern cybersecurity, companies ready to innovate will lead the market.

Take the first step now: contact our team at BTS.id for strategic consultation and discover how custom software solutions can support your company’s sustainable business growth.

Entering 2026, artificial intelligence (AI) continues to evolve from merely a supporting tool into a core foundation of global digital transformation that Software development companies must certainly adapt to this 2026 tech trend. Development such as generative language models, intelligent process automation, more efficient machine learning, and AI’s growing ability to understand context are becoming increasingly mature.

The Evolution of AI towards 2026 is making artificial intelligence increasingly smarter, autonomous, and integrated into nearly every business process, from automation and analytics to decision making. What once considered an experimental technology has now become the backbone of digital strategies across companies, public institutions, and research organizations. AI applications are now present in nearly every domain, from customer communications and process automation to executive-level decision making support.

AI is no longer making processes longer only, it is beginning to shape how businesses make decisions, innovate, and create more personalized customer experiences.

This directly impacts how software development companies operate, the service they offer, and the value they deliver to clients.

Some of these impacts include:

- Building software that is already prepared for and compatible with AI technologies

- Accelerating development processes using AI-powered tools

- Offering AI solutions to clients (chatbots, automation, data prediction)

- Ensuring software architecture is flexible and scalable for future

Some of the key drivers behind the 2026 AI development trends are:

- Machine Learning

In this case, advancements in machine learning are the primary force behind AI development trends in 2026. Larger, more efficient ML models that can understand various types of data (text, images, audio, video) will make AI in 2026:

• Smarter and more versatile

• Able to run on small devices (edge all)

• Cheaper and faster to use

• Increasingly automated through AI agents

• Safer and more transparent due to a stronger focus on Responsible AI

The advancement in Machine Learning today shapes how AI will work, evolve, and be utilized in the 2026 tech trend.

- Predictive Analytics

Predictive analytics is a key driver of AI trends in 2026 because it enables AI to automatically predict behaviors, needs, and risks. This makes systems more proactive, quicker in decision making, and capable of working in real time.

For software development companies, this capability is crucial because businesses increasingly need applications that can provide automatic recommendations, predict demand or risks, and optimize processes based on data.

In short, predictive analytics is the foundation of AI in 2026, and software development companies have to be able to integrate it so their products remain relevant and competitive.

- Software Development Innovations